Products Detail

TY03

TY03 automatic ironing machine is a new product developed by our company to the perfection of knitting production chain. This equipment is suitable for the ironing and shaping of knitted products such as sweaters. The device realizes the automatic steam ironing sweater and other knitted fabrics, replacing the original manual ironing production mode and reducing the technical requirements as well as labor intensity of the ironing workers. Greatly reduce the cost of sweater manufacturers and increase production efficiency.

The working principle of our automatic ironing machine is to put the knitted fabric on the finished setting frame, and use the steam from bottom to top to do heating and humidification of the fabric, and then utilize the fan to cool the air to achieve the purpose of shaping.

Component Description:

1 Forming device

The sizing device for fixing the fabric is controlled by a stepping motor, which can be freely adjusted according to the size required by the fabric process, and is suitable for fabrics of different specifications, and the wearing fabric is simple and convenient to operate, and the size of the same batch of fabrics is small.

2 Ironing device

The shaping frame lays the fabric on the ironing table, and simultaneously sprays the steam evenly on the fabric through the steaming holes on the ironing table, so that the fabric is heated and humidified evenly, and then the air is cooled by the suction to complete the ironing. The traditional process is hand-ironed with a steam iron, and the entire fabric cannot be heated and humidified at the same time, thus affecting the ironing effect. Our company has also controlled the ironing holes in the sub-area to reduce the waste of steam when ironing small or sleeveless fabrics.

3 Clothes-collected board device

The clothes-collected board device board is used for finishing the knitted fabric after ironing, and the finished knitting needles are automatically moved to the receiving board, and the receiving board can also be raised and lowered, and the knitted fabrics are laid flat and stacked together to reach a set number. After that, it can automatically prompt to take away the knitted fabrics.

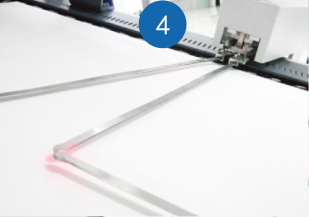

4 Infrared-positioning device

According to the shaping process of different knitting needles, the positioning of the infrared ray is used to reduce the trouble of repeatedly measuring the size and ensuring the consistency of the same type of knitted fabric.

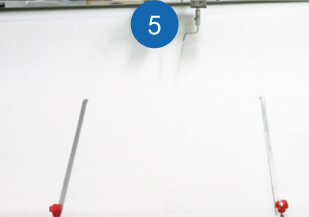

5 Transmission device

The conveying device is used for conveying the knitted fabric, placing the knitted fabric on the conveyor belt, inserting the body shaping frame and the sleeve fixing frame, and automatically transport the fabric to the receiving plate.

6 The spot spray device is mainly used for unevenness, partial thickness or other abnormalities on the surface of the fabric during the ironing process. It is touched by the knee and is flexible in operation. It is convenient to organize the fabric in time or to iron repeatedly.

7 Steam components are all imported products.

Basic parameters

| Type | Steam pressure | Pneumatic pressure | Voltage | Production capacity | Size |

| TY03 | 4~5Kg/cm² | 5~6Kg/cm² | 220V | Ordinary pullovers take about 1 minute for one piece | 3400*2900*1900mm |

Detail display

|

|

|

||

|

Collar Device

|

Receiving Plate Device |

Infrared Positioning Device

|

||

|

It is used to shape the collar size of fabric, which is controlled by cylinder; the collar size can be adjusted up and down. |

The receiving plate can move up and down to make the fabric stacked neatly, when the fabric stacked for a set quantity, machine will stop automatically to let the fabric be collected. |

After adjusting sizing dimension according to the different knitting fabric shaping process, the infrared positioning is achieved, which reduces the repeated measurement on size, and the consistency of the same code knitting fabric can be guaranteed. |

||

|

|

|

|

|

|

|

|

|

||

|

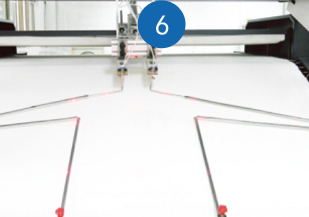

Automatic Telescopic Arm

|

Automatic Clothes Adjusting Device |

Transmission Device

|

||

|

Used for sleeves of shaped fabric, it can adjust the position of the entire arm in the ironing table according to size and length of fabric, and the position of sleeve shaped frame can be also adjusted, as well as the open angle of forming frame. |

According to the required size of knitted fabric, the width of body shaping frame can be automatically adjusted. When the steam setting is used, the knitted fabric is kept in a tight condition, easy to ensure the size of the knitted fabric. After shaping, the setting frame will automatically relax the fabric, which is convenient for the knitted fabric to exit the setting frame.

|

Transmission device is used for the transfer of knitted fabric. After the knitted fabric is sent into the conveyor belt, and set into shaped frame, sleeve forming frame, and collar forming frame, the fabric will be then sent to the secondary shaping ironing table, and later sending it to the receiving plate.

|

||

|

|

|

||

|

Hand Pressure Plate |

Jog-Moving Rod Device |

|

||

|

Matched with jog-moving rod device, it can realize clothing local finishing thermal insulation. |

With the function of point steam sprayer, it is convenient to arrange the fabric in time in order to facilitate the local manual processing. |

|