Products Detail

Cixing Production Line-C Series

Basic parameters

| Voltage(V) | Total power(Kw) | Production capacity(pairs/h) | Total gas pressure(Mpa) | Overall dimensions(m) |

| AC 380/220 | 150 | 240 | 6.3 | 60*6 |

Detail display

|

|

|

||

|

Central Control Interface

|

Vamp Spray

|

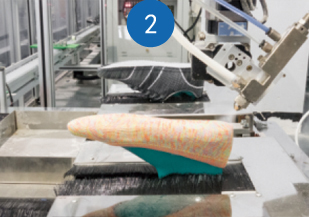

Outsole Spray

|

||

|

1. The central control system adopts a multi-functional integrated design, which can set the planned output, oven temperature and conveyor line speed on the system, view the current output, oven temperature and the operating status of the production line in real time, and adjust the running speed of the assembly line according to the actual situation. 2. This system also integrates RFID reading and writing functions and the RFID chip can be used to write the robot’s running glue program on the system. |

1. The shoe upper sprayer adopts a high-precision 5-axis hybrid robot with repeatable positioning accuracy of 0.02mm, high dispensing accuracy and easy operation. 2. The shoe upper spray station adopts double station in and out mode. It can produce two different types of shoes at the same time. The upper machine platform has a spray gun cleaning device to ensure that the spray gun is in a normal state during continuous production. |

1. Outsole spraying workstation adopts high-precision 5-axis hybrid robot with repeatable positioning accuracy of 0.02mm, high dispensing accuracy and easy operation. 2. The station of the outsole spraying work station adopts the double stations in and out way, can produce two kinds of different outsole at the same time on the line, the shoe top machine platform has the spray gun cleaning device, guarantees the spray gun is in the normal condition in the continuous production. |

||

|

|

|

|

|

|

|

|

|

||

|

3D Vision Spraying System (Optional)

|

Robot System

|

Double-Layers Assembly Line Design

|

||

|

1. Advantages: Solving the problem that the robot needs manual teaching. The spraying track of the outsole is automatically generated by the 3D vision system and can be automatically generated in real time (the outsole of different sizes can be automatically identified). The recognition speed is fast and the glue spray is precise and high. 2. Application range: UV radiation and sealing glue process (the glue-sealed outsole could be stored for one month, directly heating and bonding when needed.) |

The robot system is designed with a shock-proof and water-resistant hand wheel that can quickly and accurately move the robot to the user’s desired position. The teaching box comes with a USB port and the expense of U disk is inserted to facilitate the timely backup of track date to prevent loss. This system has shoe size zoom and mirror function, shoe type switching time is short (one shoe size switching time within 30min) |

The double-layer assembly line uses POM’s high-wear-resistant material carrier to achieve synchronized spray and entry into the oven on the outsole and vamp parts. The delivery efficiency is high. A number of patents have been granted. |

||

|

|

|

|

|