Products Detail

TY02

TY02 automatic ironing machine is a new product developed by our company for the perfection of knitting fabric production chain. It is suitable for the ironing and shaping of knitted products such as sweaters. The device realizes automatic knitting of knitted fabrics such as sweaters, replacing the original manual ironing production mode and reducing the technical requirements as well as labor intensity of the ironing workers. Greatly reduce the cost of sweater manufacturers and increase production efficiency.

The steam of the machine is sprayed from top to bottom, so that the steam directly and evenly acts on the fabric to complete the heat setting. At the same time, the centrifugal fan is used to draw air from the bottom of the ironing table to complete the dehumidification and cold setting of the fabric, and to improve the working environment of the operator. The temperature of the steam box is controllable. In addition to reducing the condensed water, the steam temperature can be adjusted according to the material of the fabric to achieve the best setting effect. The machine also has a jog jet function, which is convenient for finishing the fabric in the ironing process, and is more convenient for manual processing of the fabric. The body and sleeves are easy to adjust and the structure is stable and reliable, thus ensuring the effect of ironing. The machine also has an automatic pick-up function.

Basic parameters

| Type | TY02 |

| Type | 4-4.5 Kg/c㎡ |

| Pneumatic pressure | 5-6 Kg/c㎡ |

| Voltage | 220V |

| Size | 4250*2520*1800mm |

| Weight | 700kg |

Detail display

|

|

|

||

|

Collar Device |

Receiving Plate Device

|

Infrared Positioning Device

|

||

|

It is used to shape the collar size of fabric, which is controlled by cylinder, the collar size can be adjusted up and down. |

The receiving plate can move up and down to make the fabric stacked neatly, when the fabric stacked for a set quantity, machine will stop automatically to let the fabric be collected. |

After adjusting sizing dimension according to the different knitting fabric shaping process, the infrared positioning is achieved, which reduces the repeated measurement on size, and the consistency of the same code knitting fabric can be guaranteed. |

||

|

|

|

|

|

|

|

|

|

||

|

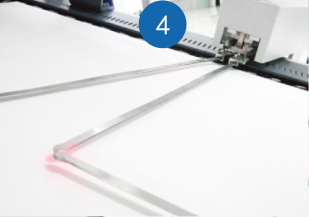

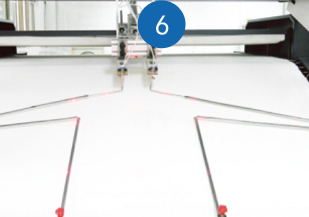

Automatic Telescopic Arm

|

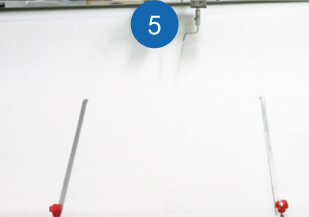

Automatic Clothes Adjusting Device

|

Transmission Device

|

||

|

Used for sleeves of shaped fabric, it can adjust the position of the entire arm in the ironing table according to size and length of fabric, and the position of sleeve shaped frame can be also adjusted, as well as the open angle of forming frame. |

According to the required size of knitted fabric, the width of body shaping frame can be automatically adjusted. When the steam setting is used, the knitted fabric is kept in a tight condition, easy to ensure the size of the knitted fabric. After shaping, the setting frame will automatically relax the fabric, which is convenient for the knitted fabric to exit the setting frame. |

Transmission device is used for the transfer of knitted fabric. After the knitted fabric is sent into the conveyor belt, and set into shaped frame, sleeve forming frame, and collar forming frame, the fabric will be then sent to the secondary shaping ironing table, and later sending it to the receiving plate. |

||

|

|

|

||

|

Hand Pressure Plate

|

Jog-Moving Rod Device

|

|

||

|

Matched with jog-moving rod device, it can realize clothing local finishing thermal insulation. |

With the function of point steam sprayer, it is convenient to arrange the fabric in time in order to facilitate the local manual processing. |

|