Products Detail

STG2.114C 12G/14G|STG3.132C 12G/14G

This model is a high-speed and high-efficiency type with a maximum speed of 1.6m/s. The hard-ware is equipped with a motor connecting rod. Compared with the magnet-seat type connecting rod, the large rod wear is eliminated, the single-port intermediate rotation can be realized, the rotation distance is shortened, the swing control position is more accurate, and the ultra-small head design can be improved efficiency by about 20%. The machine realizes multi-segments stitch knitting in the same line with the equipment of stitch motor with dynamic stitch function. With the tight tuck electron, it is available to realize the function of tuck stitch, meeting the elastic of tight tuck density, so that improving the 3D effect of shoes.

These series uses digital technology to achieve the patterns of weaving, pointel, tuck, tight tuck, apparent shape, hidden shape, intarsia, floatless intarsia and other irregular structure patterns.

Product specification

| STG2.114C 12G/14G | STG3.132C 12G/14G | |

| Gauge | 12/14G | |

| Knitting width | 45 Inches | 52 Inches |

| Knitting system | Single carriage with double systems | Single carriage with triple systems |

| Machine system | Logical system | |

| Knitting speed | Max speed 1.6m/s;128 section programmable speed | |

| Stitch density | 128 segments of electronic control,the use of subdivision technology,adjustable range:0-650 | |

| Racking | Motor driven;max 2 inches | |

| Transfer | Both front and back,not affecting by the carriage direction,sepepately knitting | |

| Sinker system | The stepping motor can adjust the active sinker,and can be adjusted according to different fabrics to achieve a pluarity of collecting and putting effects. | |

| Needle actuator | 8 section of electronic needle selector | |

| Comb device | Comb device complement with scissors/lips device, and this device adopts releasing principle, in order to effectively realize yarn hanging and sloughing function | |

| Roller device | Main roller,comb device,128 section automic control, subdivision adjustment | |

| Conveyor yarn device | Conveying yarn storage device ensures timely yarn delivery | |

| Double yarn knot antenna | The maximum yarn knot stops, and the small yarn knot runs at the lowest speed for 4 lines. | |

| Blowing device | The left side scissors machine and the falling cropping increase the blowing function, effectively reducing the false alarm stop phenomenon caused by the yarn. | |

| Color changing device | The 2*8 yarn feeder group is arranged on the left and the right sides of the 4 double side guide rails.After modifying the yarn feeder stopping point, the system reprograms the pattern and checks the yarn feeder condition. In a result to prevent the yarn feeder from being stopped incorrectly,which might cause the products falling and yarn feeders overloapping. | |

| Protection device | Automatic stopping,device if yarn broken,yarn knot,batching,striking,completion,overload,designated starting and stopping,program error happen. | |

| Driving system | Belt drive,AC servo motor control | |

| Electron connecting rod | Connecting rod driven by electron motor,to make the direction changing more accurate | |

| Tight tuck | Tuck cam controlled by the electron motor, to achieve different tighnesses of tuck, range from 0-90 | |

| Safety device | The protecting cover is equipped with stopping sensor,emergency stopping,power off device,the whole machine cover to reduce noise and dust. | |

| Date imput | Through the U disk,computer connection for direct imput of data. | |

| Fueling device | The fuel tank at the base of the needle bed refuels the carriage when the carriage is passing. | |

| Size and weight | L*W*H:2810x934x2010 mm; Net weight: 1040 kg | |

| Power supply system | Voltage: AC 220V/380V;Frequency: 50HZ/60HZ;Power:1.5KW | |

Detail display

|

|

|

||

|

Safety Device

|

Yarn Storage

|

Yarn Feeder

|

||

|

When there is an emergency and a simple maintenance work (like yarn threading, needle changing, eliminate impurities), no need to turn off the main power, press this switch to stop the machine in a locked state, preventing accident and emergency, and achieving more effective protection of human and computer security. |

Yarn Storage could reduce resistance of the conveyor yarn, and it is especially suitable for fabric with lack of elasticity and brittleness such as cashmere yarn, rabbit hair yarn, making the fabric even and smooth, as well as improving knitting efficiency. |

16 yarn feeders can be automatically knitted, and the knitting position of yarn carriers, which effectively avoids overlapping; meanwhile, the system may complete the united knitting of a lot of carriers and easily complete the knitting works of such complicated patterns such as intarsia and complete garment knitting, which greatly improves the production efficiency. |

||

|

|

|

|

|

|

|

|

|

||

|

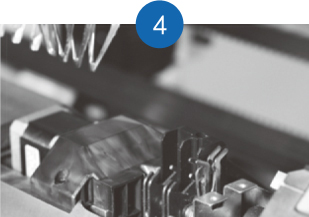

Scissors and Clips

|

||||

|

When woven products,scissors and clips complement with each other,yarn connected with the fabric and yarn of temporarily unused will be cut,This can avoid the waste yarn and product damage or because of thread is too long,possible existence of yarn winding and so hazards. Wasted time of hand-cut yarn will be save and increase efficiency,and easier to production management. |

|