Products Detail

STG-X352S

The machine adopts CPU dual-core processor. Optimize the system and make the operation of knitting become easier, timesaving, as well as display the potential of updating hardware at maximum. The system memory can be extended unlimitedly, and can input plenty of patterns and according to the requirement of producing to invoke. Optimize the program and system then only need one layer picture to display the intarsia, jacquard and partial jacquard. For the full needle shape, it has the exclusive narrowing sign, which is the same operation with single pattern, without needing to make small picture. All these contribute to optimize the processing for pattern-making personnel and enhance the production efficiency.

Product specification

| Gauge | 12G、14G、7-14G |

| Knittig width | 36/52/72 inches |

| Knitting system | Single carriage with triple systems |

| Knitting speed | Max speed 1.7m/s;24 section programmable speed |

| Racking | Motor driven;max 2 inches |

| Needle actuator | 8 section of electronic needle selector |

| Sinker system | Crossed sinker,driven by stepping motor,could be adjustable according to different weaven products,in order to reach various three-dimensional effect |

| Stitch density | 32 segments of electronic control,the use of subdivision technology,adjustable range:0-650 |

| Transfer | Both front and back,not affecting by the carriage direction,sepepately knitting |

| Roller device | High-order roller,make the cut-pieces more even and smooth |

| Motor connecting rod | Connecting rod driven by electron motor,make the direction changing more accurate |

| Adjustable tight tuck | Density of tight tuck is adjustable |

| Yarn conveyor | Conveyor yarn device or normal yarn storage setting,ensure the yarn conveyored timely |

| Yarn feeder | The 2*8 yarn feeder group is arranged on the left and the right sides of the 4 double side guide rails. |

| Driving system | Belt drive,AC servo motor control |

| Date imput | Through the U disk,computer connection for direct imput of data. |

| Protection device | Automatic stopping device if yarn broken,yarn knot,batching,striking,completion,overload,designated starting and stopping,program error happen |

| Safety devices | Emergency stop device, cut off power supply unit, alarm indicator, cover for noise and dust protection (with parking sensor) |

| Control System |

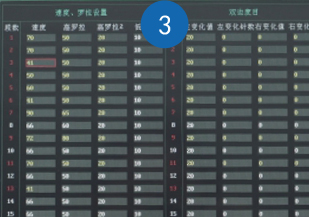

1, the screen uses LCD touch display, graphical interface, system expansion memory up to 1G, can store a large number of pattern files, can be called at any time according to production needs

2. Through the screen check, you can check the working status and actual position of the cam, and adjust it when the machine is running, which is the most convenient operation.

3, the control system (software part) and the pattern making system are easy to upgrade, for free service 4, multi-language version switching (Chinese, English, Russian and other languages)

|

| Size and weight | L*W*H:2970x940x2010 mm; Net weight: 1145 kg |

| Power supply system | Voltage: AC 220V/380V;Frequency: 50HZ/60HZ;Power:2.0KW |

Detail display

|

|

|

||

|

Bidirectional narrowing

|

Enforced knocking over

|

Bilateral stitch

|

||

|

In allusion to the transfer and some difficult fabric, this function can reduce the knitted lines. The racking is able to work simultaneously and can achieve bidirectional narrowing when the carriage operating. Just one rotation can achieve transfer, compared with a normal model that requires two revolutions to complete the needle-transferring movement, the efficiency is increased by more than 90%. |

It is easy to encase the first needle for the basic single or double jersey plain fabric. This is a global problem, but this function can solve this problem. Just start the next button in the system only, and ensure that the fabric does not have this problem.

|

The bilateral stitch of fabric can be adjusted to control the length, only need change some values. It does improve the stability and consistency of production. |

||

|

|

|

|

|

|

|

|

|

||

|

Successive knitting

|

Four Yarn Feeders |

Intelligent Program

|

||

|

The left and right pieces of the shoes are continuously woven, and the number of single or woven pieces can be set separately to continuously produce the required shoes. |

Use the four yarn feeders and two yarn feeders on each side of fabric when knitting the waste cotton. One needle knit then three needle over. Compare to the ordinary type, the line and quantity of waste cotton reduce more than 90%. |

Only need one layer picture to display the intarsia, jacquard and partial jacquard. Any one picture can complete the program. No need two-layer or three-layer pictures. |

||

|

|

|

||

|

Crossed Sinker |

||||

|

Crossed sinker is good for the molding of 3D fabric like the sock shoe in one time. |