Products Detail

HP2-45C/HP2-52C/HP2-56C

This type is single carriage with double Logical controlled system. Graphical operation interface and dynamic alarm prompt for better indication of user to operate.

The hardware is equipped with a motor connecting rod. Compared with the magnet-seat type connecting rod, the large rod wear is eliminated, the single-port intermediate rotation can be realized, the rotation distance is shortened, the swing control position is more accurate, and the ultra-small head design can be improved efficiency by about 20%. The machine realizes multi-segments stitch knitting in the same line with the equipment of stitch motor with dynamic stitch function.

These series uses digital technology to achieve the patterns of weaving, pointel, tuck, tight tuck, apparent shape, hidden shape, intarsia, floatless intarsia and other irregular structure patterns.

Product specification

| HP2-45C | HP2-52C | HP2-56C | |

| Gauge |

5G、5/7G、12G、14G、16G |

||

| Knittig width | 45 inches | 52 inches | 56 inches |

| Knitting speed | 255 seeltion,the max speed 1.6m/s.controlled by AC serve motor,serve motor will use the precise back award control and link up the high speed operation ability of digital signal prouss(DSP)to control IGBT | ||

| Knitting system | Single carriage with double systems | ||

| Weaving function | Transfer, tuck, pointel, intarsia, jacquard, apparent shape, hidden shape and other regular pattern knitting functions | ||

| Shifting | Using AC servo motor control, the shift range is up to 2 inches, with an accurate adjustment function | ||

| Probe alarm system | Probe alam | ||

| Read pin signal | IO board and head circuit board double check servo coding value | ||

| Rib transfer | Triangle composite design, single/double synergy can be either single or simultaneously transfer, can also be one system weaving the other system transferring, to achieve efficient production. | ||

| Stitch density | Controlled by stepping motor, 255 segment density selection, using subdivision technology, asjustable range:0-310, more accurate control of the length of the fabric, the use of closed loop system to monitor the current position of the motor | ||

| Sinker system | The stepping motor can adjust the active sinker, and can be adjusted according to different fabrics to achieve a pluarity of collecting and putting effects. | ||

| Comb device( C series) | Using closed U shape type compound needle with releasing principle, in order to effectively realize yarn hanging and sloughing function | ||

| Scissors and Clips | 2 scissors and 4 clips are controlled by the six individual motor, the program instructions can be carried out simultaneously or seperately, to improve work efficiency and reduce yarn waste | ||

| Batching system | Computer program instructions,stepping motor control, 255 segment tension selection, adjustable range:0-100 | ||

| Color changing system | The 2*8 yarn feeder group is arranged on the left and the right sides of the 4 double side guide rails. Modify the position of the yarn feeder | ||

| Protection system | Automatic stopping device if broken yarn, yarn knot,batching, striking, completion, overload, designated starting and stopping, program error happen, and start safety self locking protection | ||

| Language choice | Multi language version:support Chinese, English, Arabia and other languages, meanwhile according to customer's needs add the required language | ||

| Network function | High speed Ethernet(ETHERNET) network can accommodate up to 250 flat knitting machine,weaving data can be uploaded, downloaded and shared. | ||

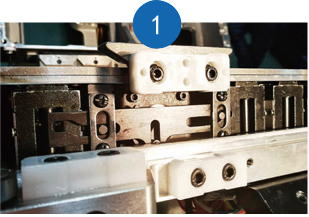

| Motor connecting rod | The connecting rod is driven by the machinery electron motor, in a result to achieve more accurate direction changing | ||

| Power supply system | Single phase 220V/three-phase 380V, using UPS power control system to ensure the case of power cut, the control system can still run normally, and immediately save the current running data. | ||

| Machine size | L*W*H:2810x934x2010 mm | L*W*H:2970x934x2010 mm | L*W*H:3070x934x2010 mm |

| Weight | 1040kg | 1130kg | 1343kg |

Detail display

|

|

|

||

|

Motor Connecting Rod |

Display Screen

|

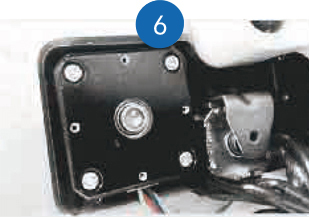

Scissors and Clips |

||

|

The connecting rod is driven by the machinery electron motor, in a result to achieve more accurate direction changing |

It adopts industry LCD displayer with graphic touch control, multi color, all time monitoring function. The data of knitting amount, time, speed, roller, stitch, yarn feeder, etc, is clearly shown and can be adjusted in the process. It is most convenient and efficient way to amend the data. |

When woven products, scissors and clips work with each other, yarn connected with the fabric and yarn of temporarily unused will be cut, This can avoid the waste yarn and product damage or because of too long thread, possible existence of yarn winding and so hazards. Wasted time of hand-cut yarn will be save and increase efficiency, and easier to production management. |

||

|

|

|

|

|

|

|

|

|

||

|

Sinker System

|

Yarn Storage

|

Dynamic Stitch

|

||

|

Flat knitting machine for knitting needle movement in the rise and fall with the regularity of the moment, to achieve the stitch transfer, stitch press off, stitch knit, stitch tuck such as knitting effects, need to help latch needle from sinker to complete, improve the capacity of weaving. Sinker control system makes the sinker adjustable. It can control and adjust according to knitting situation. The function of sinker and presser foot is very similar, but more reliable and practical than the presser foot. |

Yarn Storage could reduce resistance of the conveyor yarn, and it is especially suitable for fabric with low elasticity and brittleness such as cashmere yarn, rabbit hair yarn, making the fabric even and smooth, as well as improving knitting efficiency. |

With dynamic stitch function, using high speed stepping motor, multi-stitch function can be achieved in one line. |